Our innovative mounting solution gives you the edge.

fast. safe. easy to install.

TrapFIX – smarter than the others

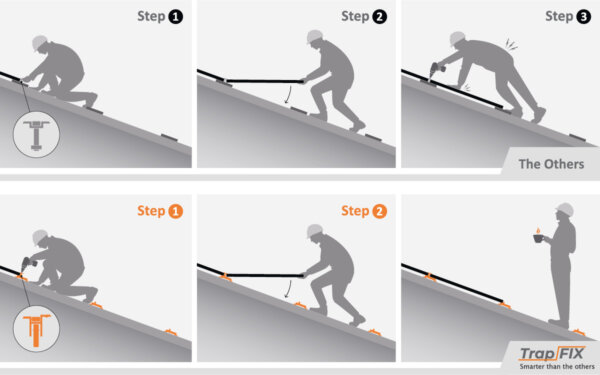

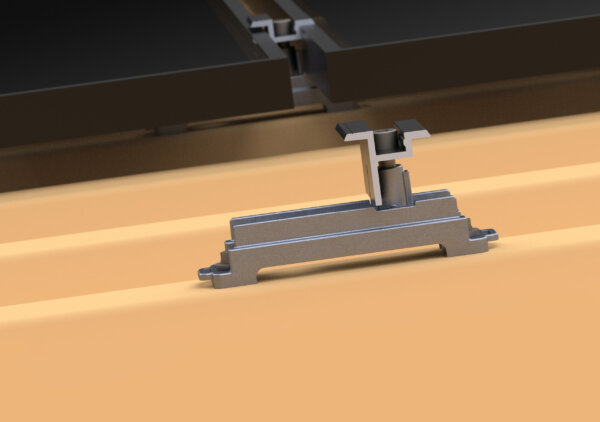

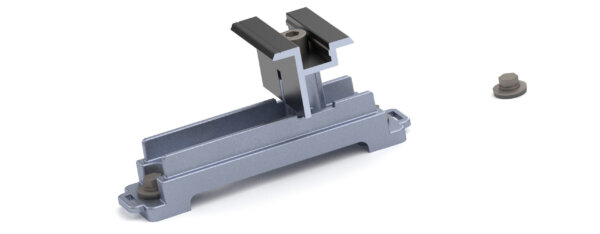

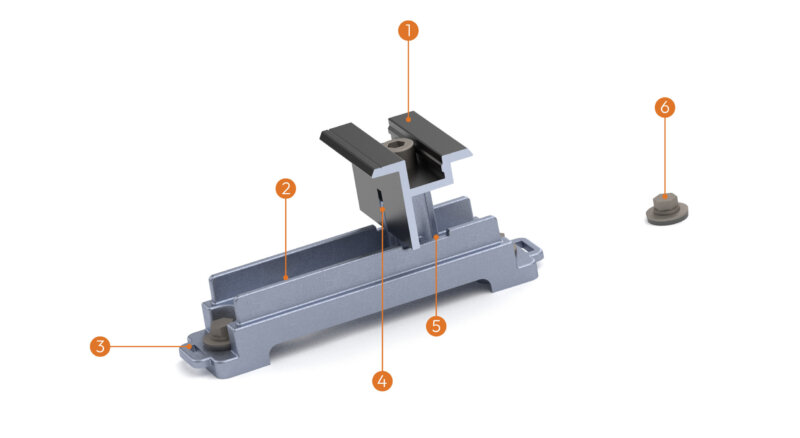

We are replacing the short rail solution for mounting modules on trapezoidal sheet metal roofs with a highly functional aluminium die-cast component with many impressive features: The insertion clamp allows easy, quick and stress-free installation without having to bend over the module. It can be used on the edge or in the centre and for different frame heights. Maximum flexibility to minimise stock levels.

The asymmetric design of TrapFIX allows you to bypass roof mounting screws with a simple 180° turn – it doesn't get any quicker than that.

The simple and compact design makes storage and transportation easy.

See for yourself!

Tension-free module installation

Universal: edge / centre / 30 – 40 mm

Low storage and transportation costs

Allows precision mounting with a gauge

Accepts module tolerances

Allows module installation from top to bottom

Integrated M8 thread for sturdy clamp connection

simple. innovative. easy to install.

Advantages

The patent-pending insertion clamp combines the simplicity of a short rail solution with the ease of insertion rail installation. The clamp is placed on the edge of the module without the installer having to bend over the module.

The two sides of the clamp are at different heights, making it easy to insert the next module. This type of installation also allows the modules to be stress-free as they are only clamped on one side at a time. This means that the modules can be easily replaced even after years on the roof and are not stressed by thermal expansion. The clamp can also be used as an edge clamp and is universal for frame heights of 30 – 40 mm.

If the foot of a TrapFIX panel accidentally strikes an existing roof mounting screw, simply rotate the TrapFIX panel 180°. Cleverly designed, the bolt in place but the feet move. This allows the roof mounting screw to be bypassed quickly and easily.

The integrated bolt of the TrapFIX element makes installation easier in a number of ways. It acts as an attachment point for the installation jig, allowing the TrapFIX element to be installed very easily and quickly with maximum precision. The precise positioning of the TrapFIX elements makes subsequent module installation much easier as they no longer need to be precisely aligned.

The bolt also prevents the modules from slipping, so they can be easily moved from the ridge to the eaves. Because the insertion clamp always leaves a small gap between the clamp and the module, the inaccuracies of the modules do not add up, further simplifying installation. The integrated M8 thread ensures a secure and durable connection to the clamp.

Two tabs at each end of the TrapFIX allow cable ties to be attached easily, quickly and securely.

The TrapFIX can be stacked inside each other through a through hole. This greatly reduces space requirements and facilitates storage, transportation and handling on site. This allows 2,400 TrapFIX to be packed per EURO pallet. TrapFIX can be packed per EURO pallet. This enables an installation of approximately 350 kWp.

Optimisers and microinverters can be attached to the TrapFIX neatly, securely and quickly using an additional aluminium bracket.

We make installation even easier with various installation aids. TrapFIX can be installed quickly, safely and accurately using a gauge to match the module width. A rope tensioner can be used to draw a straight line over long distances in all weather conditions, making it much easier to set the first line. A flexible gauge can be used to bridge the gaps during servicing.

Curious?

Assembly video

References

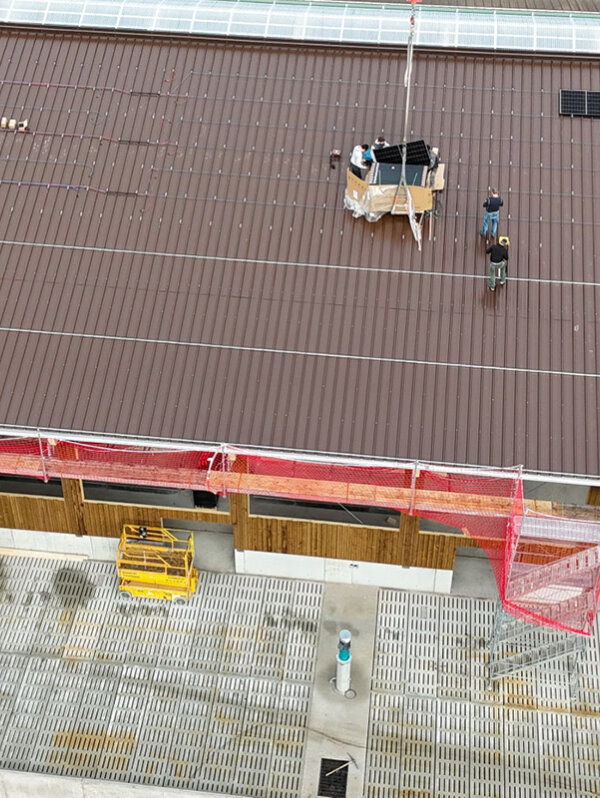

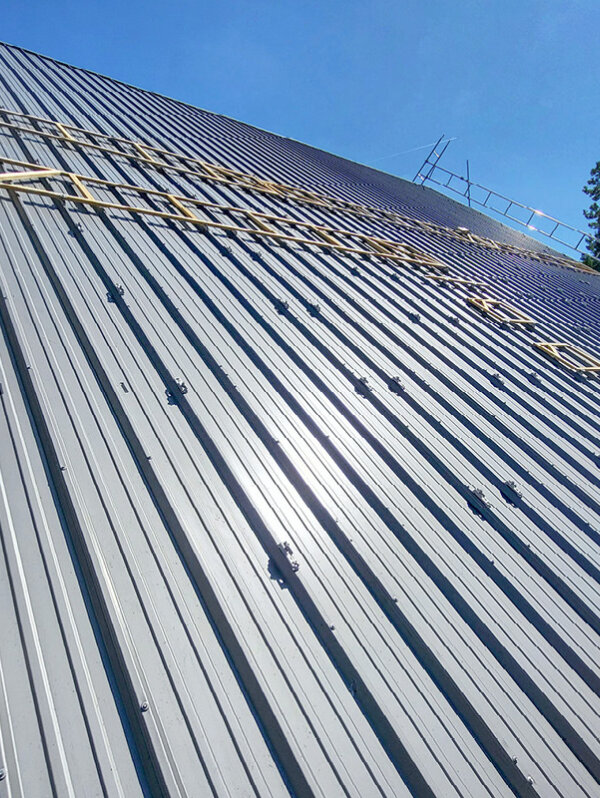

Installed by PEZAG

» pezag.ch

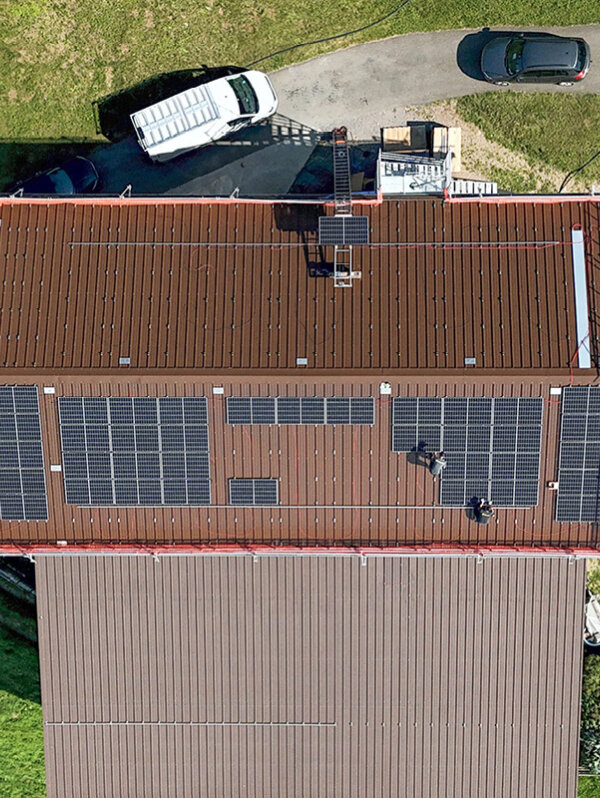

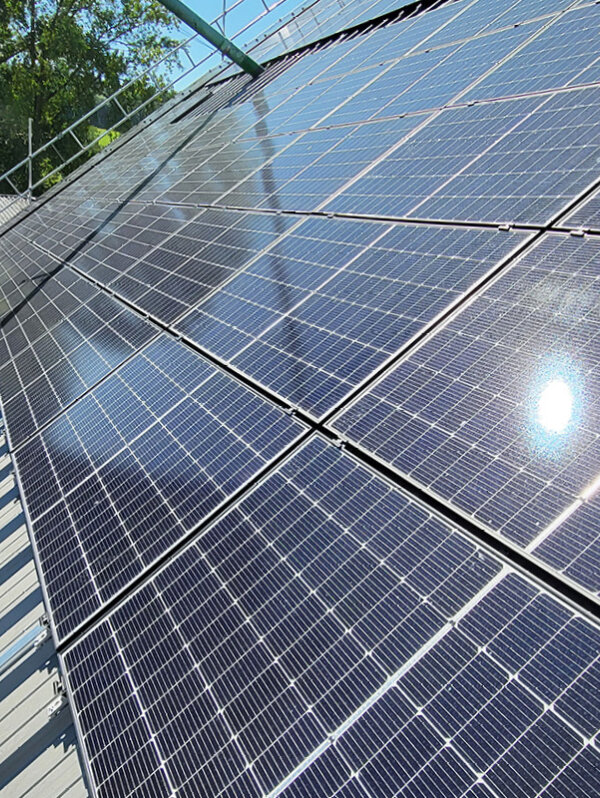

Installed by Elektro Ueli

» elektroueli.ch

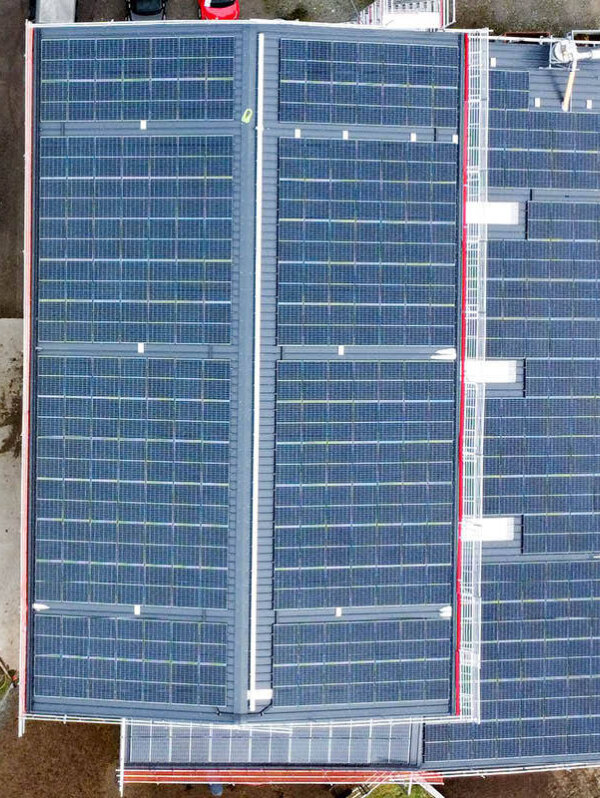

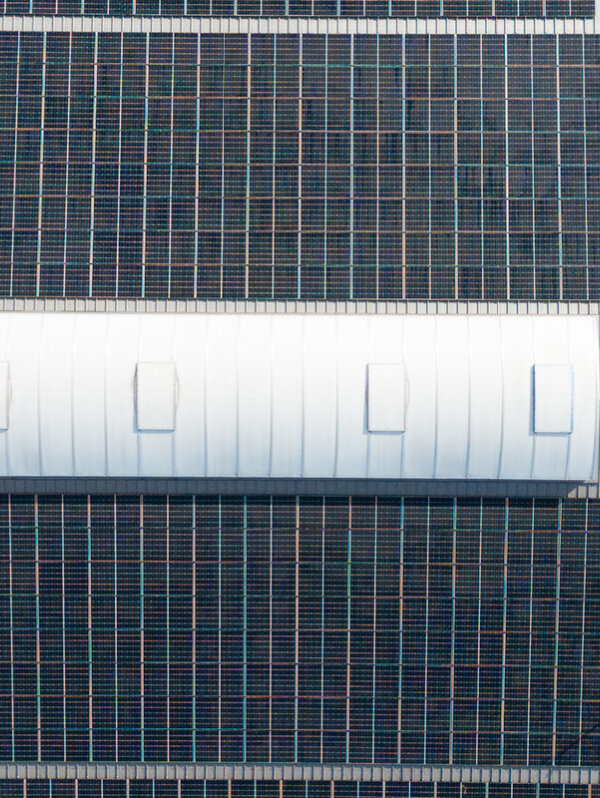

Installed and crowdfunded by Solarify

» solarify.ch

Installed by Solarify

» solarify.ch

Installed by Solarify

» solarify.ch